Material Matters: Comparing Copper and Aluminum Conductors in Automotive Wiring

In the world of automotive electrical systems, choosing the right conductor material is critical to vehicle performance, efficiency, and safety. The two most commonly used materials in automotive wiring are copper and aluminum, each offering unique advantages and trade-offs. While both materials can effectively transmit electrical current, their physical and chemical properties significantly influence how they perform in automotive environments.

As a manufacturer of custom automotive wiring harnesses, Yacenter Electric Co., Ltd. has worked extensively with both copper and aluminum conductor systems across a wide range of vehicle platforms. This article draws on that practical experience to explore the differences between these two materials, helping manufacturers, engineers, and project teams make smarter, application-specific decisions.

1. Electrical Conductivity

When it comes to conducting electricity, copper is superior.

- Copper has a higher electrical conductivity than aluminum, meaning it can carry more current with less resistance in the same gauge.

- Aluminum has about 61% of the conductivity of copper. To achieve the same current-carrying capacity, aluminum wires must be thicker, which can complicate design in space-constrained applications.

☑︎ Winner: Copper for better performance in high-load or precision circuits.

2. Weight and Flexibility

Aluminum is significantly lighter than copper—about one-third the weight. This makes it an attractive option for automotive manufacturers seeking to reduce vehicle weight and improve fuel efficiency or EV range.

- Copper wires, while more conductive, add more mass, especially in large wire harness assemblies.

- Aluminum wires can improve weight reduction in bulk wiring, but require additional design considerations due to their stiffness and expansion rates.

☑︎ Winner: Aluminum for weight-sensitive applications (e.g., EVs or commercial fleets).

3. Cost and Availability

Copper is a scarcer and more expensive resource compared to aluminum.

- Aluminum offers significant cost savings, particularly when used in high-volume production.

- However, cost efficiency must be weighed against engineering complexity (e.g., larger wire sizes, additional termination considerations).

☑︎ Winner: Aluminum, especially for large-scale, budget-sensitive projects.

4. Durability and Corrosion Resistance

- Copper is more durable and resistant to corrosion, making it ideal for harsh automotive environments (engine compartments, underbody, high humidity).

- Aluminum is more susceptible to oxidation and galvanic corrosion, especially when joined with dissimilar metals. This requires protective coatings or special connectors to maintain reliability.

☑︎ Winner: Copper, particularly in high-heat or moisture-prone zones.

5. Termination and Joint Reliability

Copper’s softness and stability make it easier to crimp, solder, and connect reliably over time.

- Aluminum, due to its higher thermal expansion and lower malleability, presents greater challenges with connector loosening or contact resistance over time.

- Automotive OEMs using aluminum often require special terminal designs or anti-oxidation pastes.

☑︎ Winner: Copper for ease of integration and long-term electrical contact reliability.

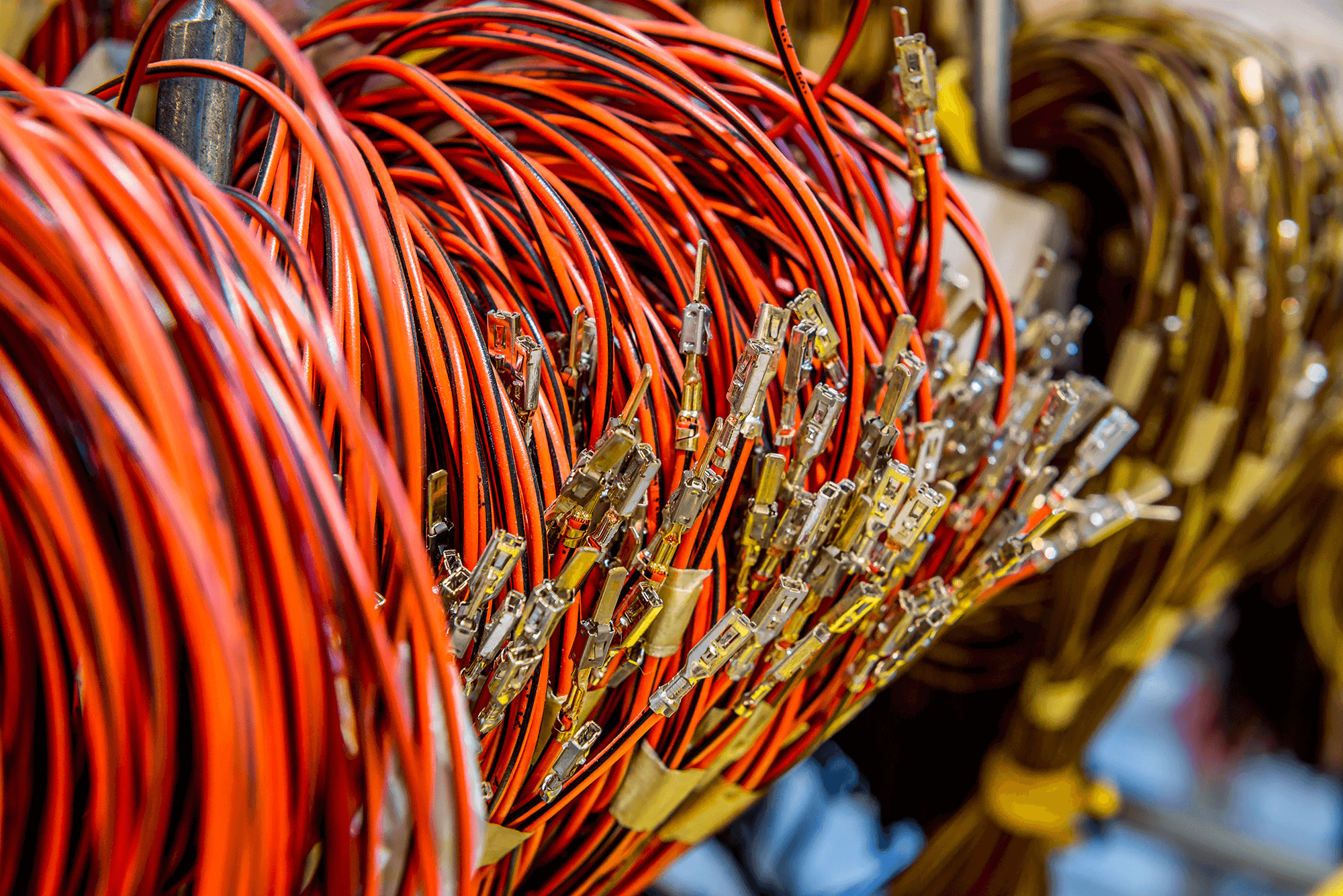

6. Application in Automotive Wire Harnesses

Yacenter Electric Co., Ltd. specializes in manufacturing automotive wire harnesses using both copper and aluminum solutions, depending on customer requirements. Copper remains the top choice for:

- High-precision circuits

- Safety-critical systems

- Harsh environments

Aluminum is selectively used for:

- Bulk power delivery circuits

- Weight-reduction strategies

- Custom cost-effective applications

Our IATF 16949-certified production ensures both copper and aluminum harnesses are engineered to meet the highest industry standards in performance, durability, and safety.

Comparison Table: Copper vs. Aluminum in Automotive Wiring

| Feature | Copper | Aluminum |

|---|---|---|

| Conductivity | Excellent | Moderate (61% of copper) |

| Weight | Heavier | Lightweight (≈ 33% of copper) |

| Cost | More expensive | Cost-effective |

| Durability | High corrosion resistance | Requires protection from oxidation |

| Flexibility | More flexible and easier to work with | Stiffer and requires special handling |

| Termination | Easy to crimp/solder | Needs special terminals |

Conclusion

When comparing copper vs. aluminum conductors in automotive wiring, there is no one-size-fits-all answer. Copper offers superior conductivity, durability, and long-term stability, making it ideal for most automotive applications. Aluminum, on the other hand, is lighter and more affordable, which can be advantageous in large-scale or weight-sensitive vehicle designs.

Yacenter Electric Co., Ltd. helps clients choose the right material based on performance needs, cost targets, and design priorities. Whether you're developing EVs, traditional vehicles, or custom wire harness systems, we deliver tailored solutions that balance performance and efficiency.

☞ Contact us today to learn how we can support your project with the right conductor materials and high-quality wire harnesses.