The Critical Role of Wire Gauge Selection in Vehicle Electrical Systems

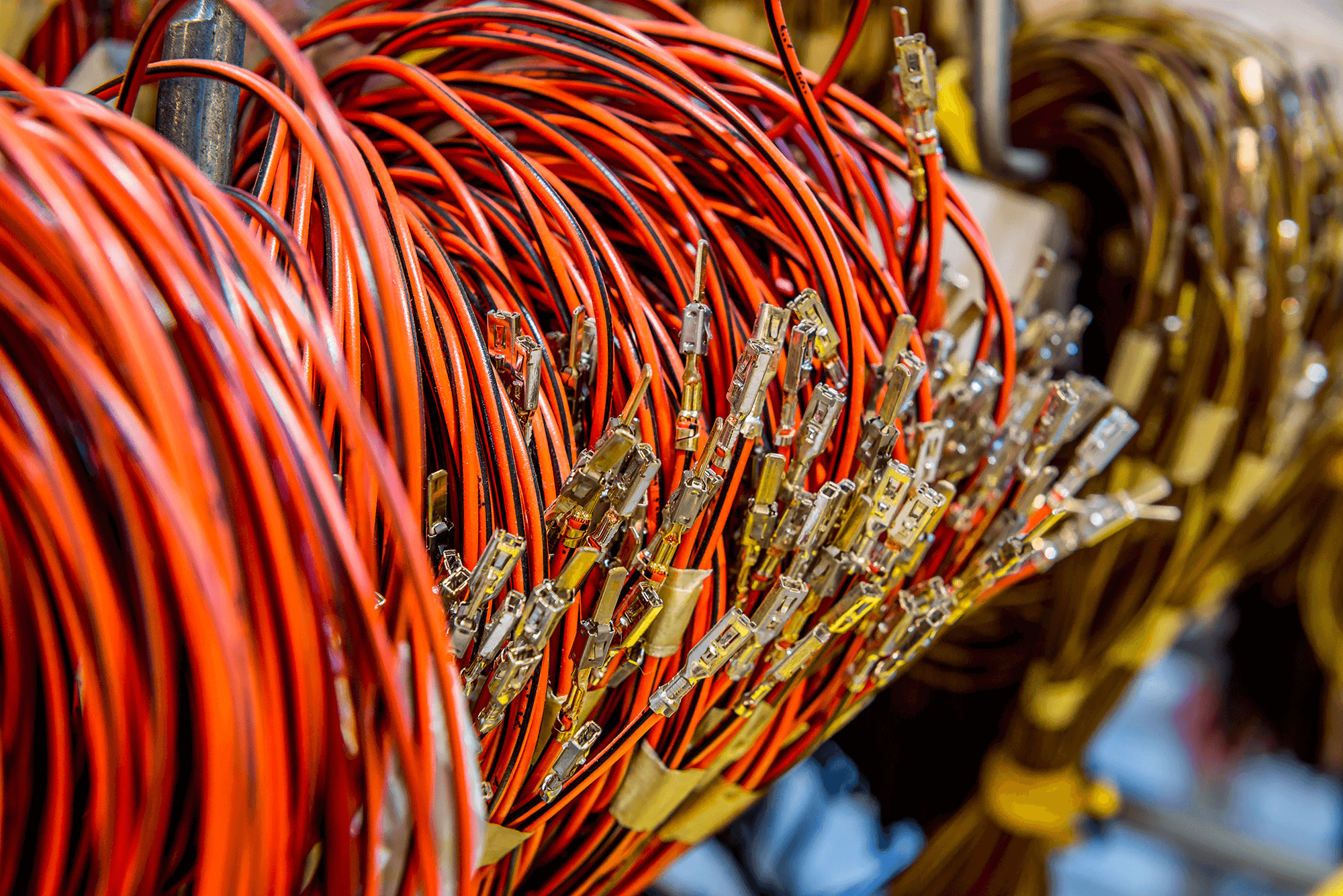

At Yacenter Electric Co., Ltd., we specialize in designing and manufacturing high-quality wire harnesses for a wide range of vehicles and heavy equipment. One of the most important aspects of our work is ensuring that every wire in a harness is carefully selected to meet the specific electrical requirements of the system it supports. Among the many factors that contribute to a reliable and efficient electrical system, choosing the correct wire gauge is one of the most critical.

Wire gauge directly impacts three key aspects of an electrical system: voltage drop, current capacity, and overall efficiency. In this article, we will explore these factors in detail and explain why proper wire gauge selection is essential for maximizing the performance and safety of vehicle electrical systems.

Understanding Wire Gauge and Its Importance

Wire gauge refers to the thickness of an electrical wire, typically measured using the American Wire Gauge (AWG) system. In this system, a smaller gauge number indicates a thicker wire, while a larger gauge number represents a thinner wire. The thickness of the wire determines its resistance, current-carrying capacity, and ability to minimize power loss.

In vehicle electrical systems, wires are responsible for transmitting power to critical components such as engines, lights, sensors, and control modules. Selecting the wrong wire gauge can lead to a range of problems, including overheating, voltage instability, and even system failure.

At Yacenter Electric Co., Ltd., we take a meticulous approach to wire gauge selection, ensuring that every wire harness we produce is optimized for the specific requirements of the application.

1. Voltage Drop: A Key Factor in System Performance

Voltage drop occurs when electrical energy is lost as it travels through a wire due to resistance. This is especially problematic in vehicle electrical systems, where long wiring runs are common, particularly in larger vehicles such as trucks, buses, and heavy equipment.

How Wire Gauge Affects Voltage Drop

- Thinner Wires (Higher Gauge Numbers): Have higher resistance, which increases the voltage drop over long distances.

- Thicker Wires (Lower Gauge Numbers): Have lower resistance, reducing voltage drop and ensuring more consistent power delivery.

Impact of Voltage Drop on Vehicle Systems

- Lighting Systems: Reduced brightness or flickering lights.

- Motors and Actuators: Insufficient power can lead to sluggish or erratic operation.

- Control Modules: Voltage fluctuations can disrupt sensitive electronics, leading to errors or malfunctions.

At Yacenter Electric Co., Ltd., we calculate voltage drop for every wire in the harness during the design phase to ensure that all components receive the power they need to operate reliably.

2. Current Capacity: Ensuring Safety and Reliability

Every wire has a maximum current capacity, also known as ampacity. This is the amount of electrical current the wire can safely carry without overheating. Selecting a wire gauge that is too small for the current it needs to carry can lead to serious safety issues, including:

- Overheating of the wire and surrounding components.

- Melting of insulation, which can cause short circuits or fires.

- Premature failure of the electrical system.

Factors That Influence Current Capacity

- Wire Material: Copper wires have higher conductivity than aluminum wires, allowing them to carry more current for a given gauge.

- Insulation Type: High-temperature insulation can increase a wire's ampacity.

- Ambient Conditions: Wires in hot environments or enclosed spaces may require larger gauges to prevent overheating.

Yacenter Electric Co., Ltd. carefully analyzes the current requirements of each system and selects wire gauges that provide a safe margin above the maximum expected load. This ensures that our wire harnesses can handle peak currents without compromising safety or reliability.

3. Overall Efficiency: Optimizing Energy Use

Efficiency is a critical consideration in modern vehicle design, particularly as manufacturers strive to reduce energy consumption and emissions. Using the correct wire gauge is essential for minimizing energy loss and maximizing the efficiency of the electrical system.

How Wire Gauge Affects Efficiency

- Thinner Wires: Higher resistance leads to greater energy loss in the form of heat.

- Thicker Wires: Lower resistance reduces energy loss, ensuring more power reaches the intended components.

Balancing Efficiency and Cost

While thicker wires are more efficient, they are also heavier and more expensive. Using unnecessarily thick wires can increase the weight of the vehicle, reducing fuel efficiency and driving up costs.

At Yacenter Electric Co., Ltd., we strike the perfect balance between efficiency and cost by selecting wire gauges that meet the system's requirements without adding unnecessary bulk or expense.

4. Practical Applications in Vehicle Electrical Systems

Heavy Equipment and Construction Vehicles

In heavy equipment such as excavators and bulldozers, long wiring runs and high-current loads are common. Selecting the correct wire gauge ensures reliable operation of critical systems, such as hydraulics, lighting, and engine controls, even in harsh environments.

Agricultural Machinery

Tractors and harvesters often operate in extreme conditions, where temperature fluctuations and mechanical stress can affect electrical performance. Proper wire gauge selection helps maintain system reliability and prevent downtime during critical farming operations.

Commercial and Passenger Vehicles

Modern vehicles are equipped with advanced electronics, including infotainment systems, driver-assistance features, and electric powertrains. Choosing the right wire gauge is essential for ensuring these systems operate efficiently and without interference.

Our Commitment to Quality and Precision

At Yacenter Electric Co., Ltd., we pride ourselves on delivering wire harness solutions that meet the highest standards of quality and performance. Our team of experts works closely with clients to understand their specific needs and design wire harnesses that are:

- Custom-Tailored: Every harness is designed to match the exact requirements of the vehicle or equipment.

- Highly Reliable: We use only the best materials and manufacturing processes to ensure long-lasting performance.

- Cost-Effective: By optimizing wire gauge selection, we help our clients achieve the perfect balance of performance, safety, and efficiency.

Conclusion

Choosing the correct wire gauge is not just a technical detail—it is a fundamental aspect of designing safe, reliable, and efficient vehicle electrical systems. Yacenter Electric Co., Ltd. brings decades of expertise to every project, ensuring that our wire harnesses deliver exceptional performance in even the most demanding applications.

Whether you need a solution for heavy equipment, agricultural machinery, or commercial vehicles, you can trust us to provide wire harnesses that meet your exact specifications. Contact us today to learn more about our products and services.