The Impact of Wire Gauge Selection on Automotive Electrical System Performance

In modern vehicles, electrical systems are becoming more complex, and precision in every detail — including wire specifications — is essential. One of the most critical factors that affects performance, efficiency, and safety is wire gauge selection.

As a certified IATF 16949 manufacturer, Yacenter Electric Co., Ltd. not only specializes in automotive wire harness production but also understands how wire gauge directly influences the reliability of a vehicle’s complete electrical system. In this article, we explore how wire gauge works — and why it's a key design factor in high-quality wire harnesses.

________________________________________

What is Wire Gauge and Why Does It Matter?

Wire gauge refers to the thickness (diameter) of an electrical wire, which determines its current-carrying capacity, resistance, and heat generation. In automotive applications, commonly used standards include:

- AWG (American Wire Gauge)

- AVSS / AVS (Automotive standards by JASO)

Using the wrong gauge can result in:

- Overheating and premature failure

- Voltage drop that causes sensitive devices to malfunction

- Safety risks, especially in high-current zones like engine bays or EV batteries

________________________________________

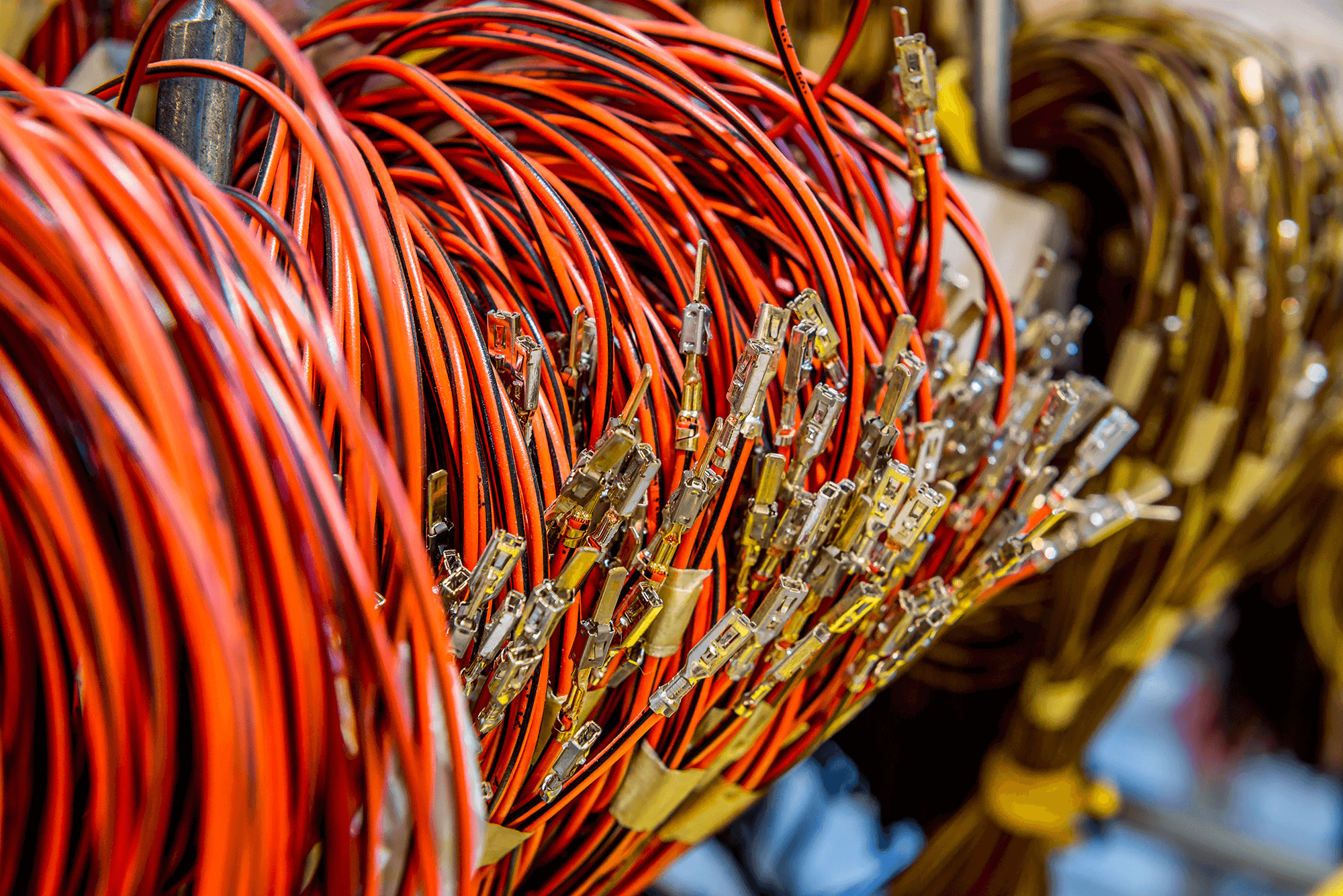

The Role of Wire Gauge in Wire Harness Design

A wire harness is more than just a bundle of wires — it's a custom-engineered system that combines multiple wires of different gauges, connectors, protective sleeves, and mounting components into a single, efficient assembly.

Wire harnesses are used in:

- Power distribution (e.g., from battery to ECU)

- Signal transmission (e.g., sensors, lighting, infotainment)

- Safety-critical systems (e.g., airbags, ABS, ADAS)

Wire gauge selection within a harness is strategic.

Each circuit in the harness must be designed to:

- Carry the required current without excessive heat

- Maintain signal integrity over the necessary length

- Fit within spatial constraints (smaller gauges reduce harness bulk)

By optimizing wire gauge for each circuit, engineers improve both the performance and efficiency of the entire wiring system.

________________________________________

How Incorrect Gauge Selection Can Affect System Performance

| Issue | Cause (Wrong Wire Gauge) | Result |

|---|---|---|

| Voltage drop | Wire too thin for current load | Weak signal or device malfunction |

| Overheating | Excessive resistance in undersized wire | Melting insulation, fire risk |

| Oversized wires | Using unnecessarily thick wires | Added weight and bulk in the harness |

| EMI / Signal loss | Improper gauge for communication wires | Sensor errors or data loss |

In automotive wire harness design, these issues are avoided through careful gauge calculations, testing, and adherence to international standards like ISO 6722 and JASO D611.

________________________________________

Yacenter's Approach: Quality Starts with the Right Gauge

At Yacenter Electric Co., Ltd., we incorporate wire gauge optimization into every stage of our wire harness manufacturing process. Our engineers analyze:

- Current requirements for each circuit

- Routing length and environment (heat, vibration, moisture)

- Connector and terminal specifications

- OEM customer standards and regulations

Whether designing for internal combustion vehicles, hybrid systems, or EVs, we ensure the wire gauge is perfectly matched to each application. Our IATF 16949 certification ensures that every step — from material sourcing to final testing — meets strict quality standards recognized by leading automotive brands.

________________________________________

Why the Right Wire Gauge Builds Long-Term Trust

Choosing the correct wire gauge is not just about technical compliance — it's also about long-term durability, reduced warranty costs, and user safety. For manufacturers and OEMs, working with a supplier like Yacenter means:

- Consistent quality across all wire harness batches

- Accurate documentation and traceability of wire specs

- Confidence that every wire, connector, and gauge has been selected with purpose

________________________________________

Conclusion

Wire gauge selection is the foundation of a reliable automotive electrical system. When done right — especially within a professionally engineered wire harness — it reduces failures, improves performance, and ensures that every component functions as expected.

At Yacenter Electric Co., Ltd., we integrate precise wire gauge planning into every harness we produce. With decades of experience and IATF 16949 certification, we deliver customized, high-performance wiring solutions that meet the evolving needs of today's automotive industry.

Looking for a trusted wire harness supplier? Contact Yacenter today to discuss your project needs.